|

The Story of RelayMan

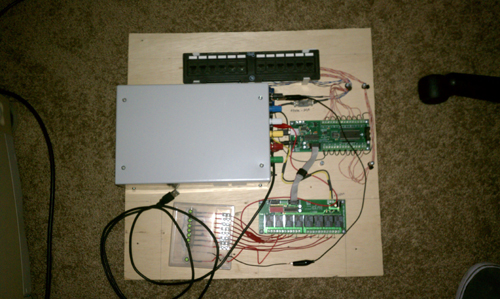

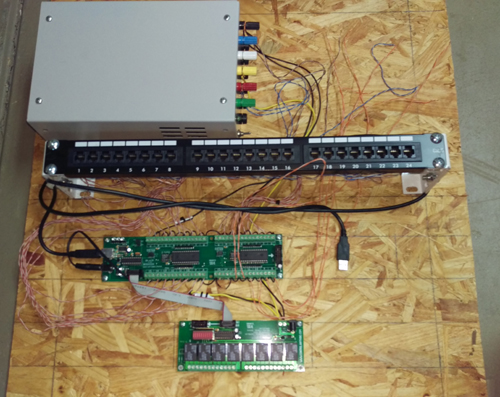

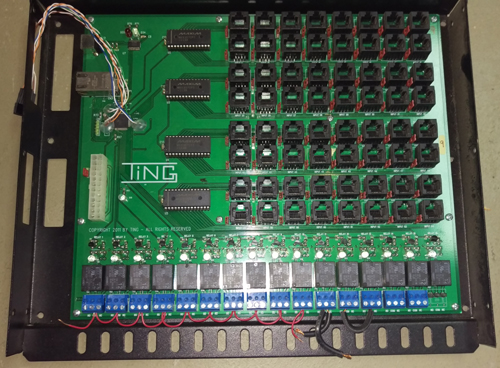

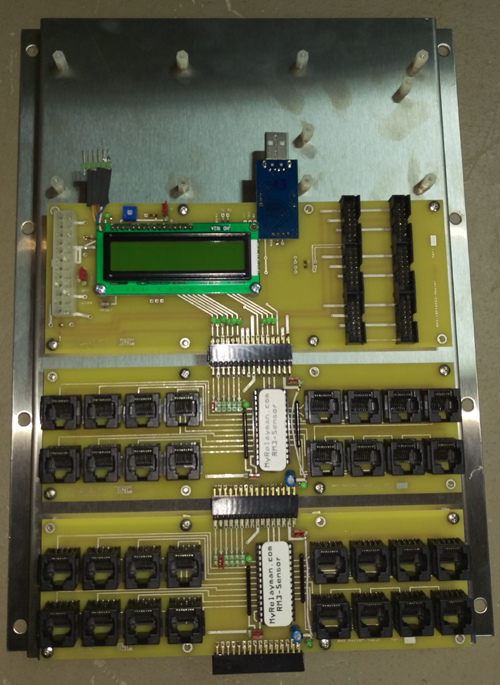

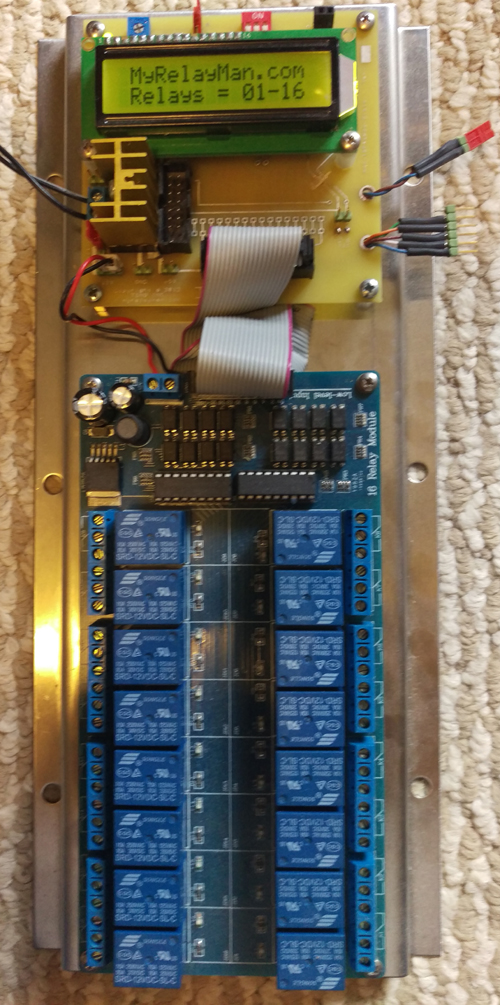

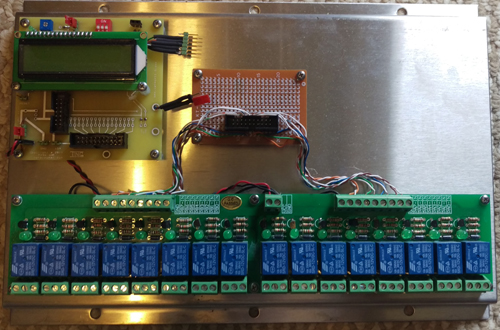

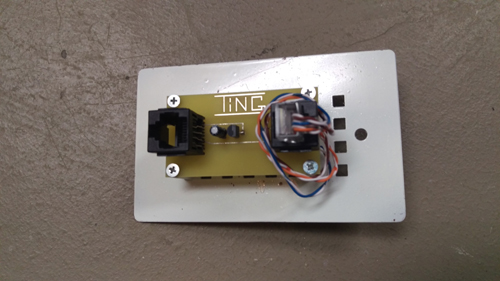

While working for a client there was a need for control of circuits, turning on and off these circuits at various intervals and for various reasons or conditions. Searching the internet for an off the shelf solution was uneventful and out of this unavailable need RelayMan was created. 2010 - RelayMan #1 – was created by using analog to digital converters and relay modules from National Control Devices in Osceola Missouri. The ProXR modules from NCD were very easy to use with the company’s software however for anything custom you had to write our own software. Fortunately the ProXR devices came with SDK. We purchased the UAD1216PROXR A/D Converter as the input source and the XR810 XR Expansion Board as the output relay source. The design of the RelayMan software was Windows based and created in Visual Basic (Screen Shots of RM1). The software would be installed on a dedicated computer or laptop that was connected to the system via USB cable. The dedicated computer or laptop would process all the inputs and outputs handle the notifications and log the data to history. We installed 7 of these systems. 2011 – RelayMan #2 – was created because the ProXR modules from NCD were expensive and becoming harder to deal with the exceptions and logic we wanted to accomplish. The power was an issue and there was not a clean solution. The installation looked very thrown together. We needed a more professional looking board and installation. We created the big green board with 64 A/D inputs and 16 Relays build right onto the board. We created it so it would get power from a standard ATX desktop computer power supply thus giving us enough power to run the board and all the inputs and relays. We mounted the board in a custom designed powder coated enclosure. The main software received some enhancements (Screen Shots of RM2) but still connected to a dedicated computer or laptop via USB cable for processing. RelayMan #2 received many add-ons as well. We created our own group sensors using POE (Power Over Ethernet) for communications. Now having a big 450W ATX power supply we were able to put sensors all over the place within a 330ft limitation of cat5 cable. We created the 5-Sensor Board (5SB) with temperature, light, humidity, contact and customer definable sensors all on 1 board. The 5SB had a resister bank and jumpers to select which 2 sensors the customer wanted to send data back for. The next sensor we created was the wall plate temperature zone comfort control (ThermoPot). The software was modified again (Screen Shots of RM 2.2) and the ThermoPot was included into the logic screen giving the customer the ability to have 0-5vdc value over any given range. When calibrating the ThermoPot the customer would turn it all the way down and type in the low value, then they would turn the ThermoPot all the way up and enter the high value. The system would calculate the values from low to high over the difference in voltage from low to high. We installed 5 of these systems and upgrade the same 2 existing RelayMan #1->RM2 systems. 2012 – RelayMan#3 – was created as an ala carte sensor and relay system. With RelayMan #2 being fixed 64 inputs and 16 relays we soon ran into a couple installations with RelayMan #2 where the client needed more than 16 relays and some only used 5 or 6 inputs others wanted more than 64 inputs and 0 relays. This new idea would point us in the direction of treating everything as modules. A customer could order it in any configuration from 0 up to 96 inputs and 96 relays. The software again went through minor enhancements (ScreenShots of RM3) but again it was still connected to a dedicated computer or laptop via USB cable for processing. With RelayMan #3 we decided to use our sensors and source the relays out. We found the relays were readily available for sale cheap on eBay. We found a standard configuration and created our own board to communicate and mate with the generic relay boards found on eBay. This opened us up to saving more on manufacturing thus less cost to the customer. Using the relay modules we were getting from eBay we were able to offer custom configurations using “off the shelf parts” so to speak. Soon we were adapting RelayMan #3 to accept more new sensors such as water levels, water and air pressure. We installed 6 of these systems and upgrade the original 2 RelayMan #2 systems. |